Fabrication Drawings

The detailed fabrication drawings can consist of:

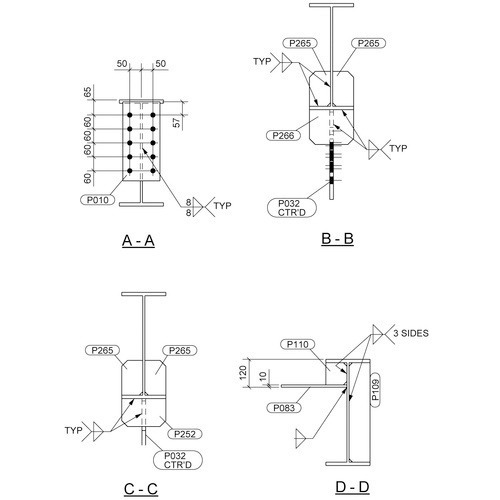

⦿ Assembly Drawings – these drawings show steel beam and plate positions

dimensioned to each other, weld type and size, hole position and size, part

numbers as well as the type of steel finishing.

⦿ Single Part Drawings – these only show one specific dimensioned part. This

could be a plate, column, beam, channel or other particular component, as

opposed to a whole assembly drawing detailing more of the whole build.

Advantages of Fabrication Drawings

⦿ Avoids errors and delays – Good CAD 3D steel detailing software specifies

every fabrication sheet to be displayed as a visual presentation of the

structure, with all parts managed and synchronised effectively. If a model

needs changes applied to it, these changes will be reflected in each steel

fabrication drawing, meaning that less manual editing is required. By

extension, there will be no errors when it comes to the steel fabrication

process – it goes without saying that fabricating steel beams to sizes that were

incorrectly detailed (and unnoticed) would be hugely frustrating for all project

parties.

⦿ Cost-saving measure – by using 3D steel detailing software, alternative models,

steel alterations and re-estimates can be calculated swiftly and efficiently. You

can estimate the amount of structural steel necessary and even potentially

generate a bill of materials, which can save you on both labour and material

costs.

⦿ Minimizes on-site issues – by using fabrication drawings, you are essentially

reducing any on-site fabrication or mobile welding issues to zero. Models can

be viewed from virtually every angle possible, and this benefit those on-site to

stay fully aware of the progress of the steel buildings’ construction.